Organic Rankine Cycle

Transform Waste Heat into Clean Power

Harness untapped thermal energy with ORC technology to boost efficiency, cut emissions, and power a more sustainable future

What is Organic Rankine Cycle (ORC ) Technology?

The ORC is a closed thermodynamic process that uses organic fluids with low boiling points to recover heat from sources ranging between 80°C and 400°C. This recovered heat is then converted into electricity through a closed-loop system, making it ideal for industries with low-grade heat emissions.industries with low-grade heat emissions.

An Organic Rankine Cycle works similarly to the traditional steam Rankine Cycle. The main difference is the use of organic substances (hydrocarbons or refrigerants) instead of water (steam) as working fluid.

Unlock the hidden potential of your industrial processes

Transforming waste heat into clean power through tailored ORC solutions

Every day, industries release vast amounts of low to medium-temperature heat into the environment. With ORC technology, this previously untapped energy can be harnessed to generate electricity, improving efficiency and sustainability.

At Ation Solutions, we partner with leading ORC technology providers to deliver customized solutions that convert waste heat into valuable power across various industrial applications.

Key Benefits of Waste Heat Recovery Systems for Sustainable Energy

Maximize energy efficiency, reduce environmental impact, and achieve operational flexibility with scalable, cost-effective solutions

Energy Efficiency

Environmental Impact

Operational Flexibility

Easy Operation

Scalability

Energy Efficiency

Utilize waste heat to generate electricity, reducing overall energy consumption.

Environmental Impact

No water consuption and lower greenhouse gas emissions by converting excess heat into usable power.

Operational Flexibility

Modular configuration, suitable for lower temperature applications with different energy sources for various heat sources, including geothermal, biomass, and industrial waste heat.

Easy Operation

Fully-automatic plant, no need for dedicated operators.

Scalability

Adaptable to different industrial scales, from small facilities to large plants.

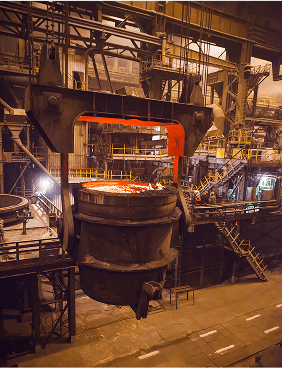

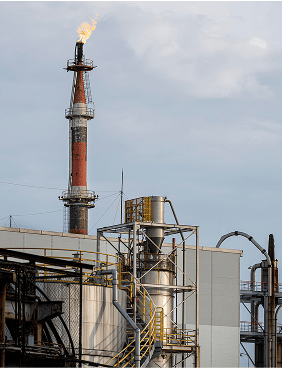

Industries Powering Efficiency

From heavy manufacturing to energy infrastructure, we help diverse sectors recover waste heat, reduce emissions, and turn energy losses into strategic gains

Manufacturing

Energy Sector

Food & Beverage

Oil & Gas

Project Developement

From feasibility to full deployment—tailored solutions that turn your waste heat into valuable energy

Feasibility Studies

Assess the potential for heat recovery and power generation in your operations.

Customized System Design

Develop tailored ORC solutions that align with your specific process requirements.

Installation & Integration

Seamlessly incorporate ORC systems into existing infrastructure with minimal disruption.

Maintenance & Support

Provide ongoing technical support to ensure optimal system performance.

Regulatory Compliance Assistance

Navigate environmental regulations and capitalize on available incentives for energy efficiency.

Frequently Asked Questions

Find quick answers to common inquiries about our technologies, services, and approach

What exactly is ORC and how is it different from a traditional steam turbine system?

ORC (Organic Rankine Cycle) systems work similarly to steam turbines but use an organic fluid with a lower boiling point. This allows the system to recover energy from lower-temperature heat sources (80–400°C), which steam systems can’t efficiently utilize.

Will installing an ORC system disrupt our existing operations or require downtime?

No significant disruption is required. ORC systems are modular and designed to integrate seamlessly into existing infrastructure. Installation can be done in parallel with your operations, minimizing any downtime.

What kind of maintenance is required, and do we need specialized personnel to run it?

ORC systems are fully automated and require minimal maintenance. There’s no need for dedicated operators. Maintenance is mainly preventive and involves basic checks, with remote monitoring for early issue detection.

How long does it take to install and commission an ORC system?

Once the system is designed and delivered, on-site installation and commissioning typically take a few weeks. From feasibility to operation, the full project can be completed in 6–12 months, depending on complexity.

How do I know if our facility has enough waste heat to justify this investment?

We conduct a detailed feasibility study that measures your heat flow, temperature profiles, and operational cycles. This analysis determines whether ORC is viable and what energy savings you can expect.

Are there any government incentives or carbon credits we can access through this technology?

Yes. ORC improves energy efficiency and can contribute to decarbonization goals, making it eligible for energy-saving grants, government incentives, and carbon credit schemes. We help you navigate and apply for these programs.

Let us help you to capitalize on opportunities in your organization

Get in touch to explore how Ation Solutions can help you improve efficiency, reduce emissions, and unlock new value