Turboexpander

Harnessing waste heat to generate Clean Energy

Unlock latent capacity within your industrial processes

What is a Turboexpander and How It Recovers Energy

Unlock the hidden energy potential within your industrial processes

Every day, industries lose valuable energy through pressure reduction processes. Turboexpanders offer an innovative solution by capturing this wasted energy and converting it into clean, usable electricity—enhancing efficiency and contributing to decarbonization efforts.

At Ation Solutions, we specialize in integrating advanced turboexpander technology into industrial systems across Latin America, partnering with leading OEMs like Sapphire Technologies to deliver tailored energy recovery solutions.

A technology that converts excess pressure into clean electricity—boosting efficiency and reducing emissions.

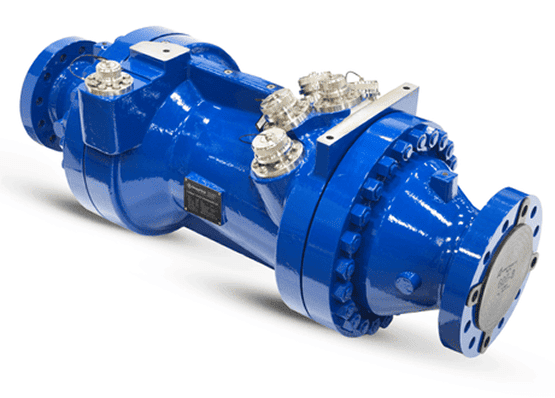

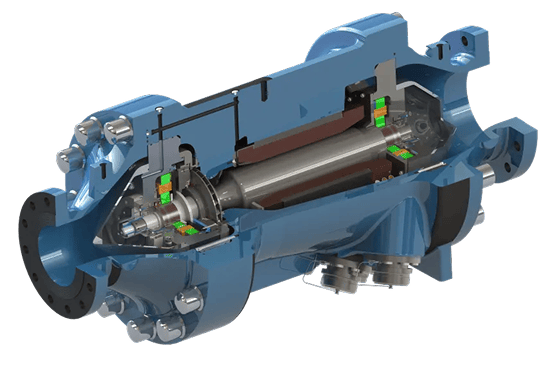

A turboexpander is a device that recovers energy from pressurized gas streams. As high-pressure gas expands through the turboexpander, it drives a turbine connected to a generator, producing electricity without additional fuel consumption or emissions.

Our Partnership with Sapphire Technologies

Advancing clean energy with cutting-edge turboexpander technology

We collaborate with Sapphire Technologies, a leader in energy recovery systems, to bring their FreeSpin® In-line Turboexpander technology to our clients. This system utilizes advanced magnetic bearings and a high-speed permanent magnet generator to efficiently convert waste pressure into electricity.

Each Each FreeSpin® system generates up to 2.6 GWh of clean energy each year, enough to light 700 homes and offset 2,000 tons CO2e, the equivalent of 4,360 barrels of oil consumed.

Turboexpander Applications Across Key Industries

Versatile energy recovery solutions for gas, hydrogen, LNG, and petrochemical infrastructure

Natural gas processing and distribution

LNG regasification terminals

Hydrogen and renewable gas networks

Chemical and petrochemical facilities

Key Benefits of Turboexpanders for Industrial Energy Systems

Boost efficiency, recover clean energy, and reduce operational complexity—all with zero emissions

Compact & Scalable:

Easily integrates into existing pressure letdown stations, with flexible configurations for a wide range of flow conditions.

Zero Emissions:

No combustion required—contributes directly to decarbonization goals.

OPEX Savings:

Reduce electricity consumption and lower operational costs.

Low Maintenance:

The hermetically sealed system uses magnetic bearings, eliminating lubrication and reducing maintenance.

Energy Recover:

Capture wasted pressure energy and convert it into clean electricity.

Compact & Scalable:

Easily integrates into existing pressure letdown stations, with flexible configurations for a wide range of flow conditions.

Zero Emissions:

No combustion required—contributes directly to decarbonization goals.

OPEX Savings:

Reduce electricity consumption and lower operational costs.

Low Maintenance:

The hermetically sealed system uses magnetic bearings, eliminating lubrication and reducing maintenance.

Energy Recover:

Capture wasted pressure energy and convert it into clean electricity.

Project Developement

At Ation Solutions, we offer end-to-end support to ensure your turboexpanders project achieves its full potential

Feasibility Assessment

Evaluate the potential for energy recovery in your operations.

System Design & Integration

Customize turboexpander solutions to fit your specific needs.

Installation & Commissioning

Seamless turnkey implementation with expert global-local support.

Monitoring & Support

Provide ongoing performance analysis and technical support.

Regulatory Compliance

Support to access incentives, energy efficiency programs, and carbon credits

Frequently Asked Questions

Find quick answers to common inquiries about our technologies, services, and approach

How does a turboexpander work?

A turboexpander captures energy from high-pressure gas streams. As the gas expands through the turbine, it spins a generator to produce electricity—without combustion or additional fuel input.

What makes Sapphire Technologies' turboexpander system unique?

Sapphire’s FreeSpin™ In-line Turboexpander is hermetically sealed, uses magnetic bearings (no lubrication required), and operates with near-zero maintenance. It’s compact, efficient, and integrates easily into existing infrastructure.

What are the main benefits of using a turboexpander system?

Turboexpanders recover energy that would otherwise be lost, reduce operational costs, and contribute to decarbonization goals with zero-emission electricity generation. They also require minimal maintenance due to advanced, sealed designs.

Is the technology complex to install in existing facilities?

Not at all. Turboexpanders are compact and scalable, making them easy to integrate into existing pressure letdown stations with minimal modifications and operational disruption.

Can turboexpander projects qualify for carbon credits or government incentives?

Yes. Since turboexpanders improve energy efficiency and reduce emissions, they may qualify for carbon credits and energy-saving incentives. We assist clients in navigating the regulatory process to access these benefits.

Is the system easy to monitor and maintain?

Yes. The FreeSpin™ system includes smart sensors, real-time performance dashboards, and predictive maintenance features—allowing hands-free operation and minimal intervention.

Let us help you to capitalize on opportunities in your organization

Get in touch to explore how Ation Solutions can help you improve efficiency, reduce emissions, and unlock new value